Introduction

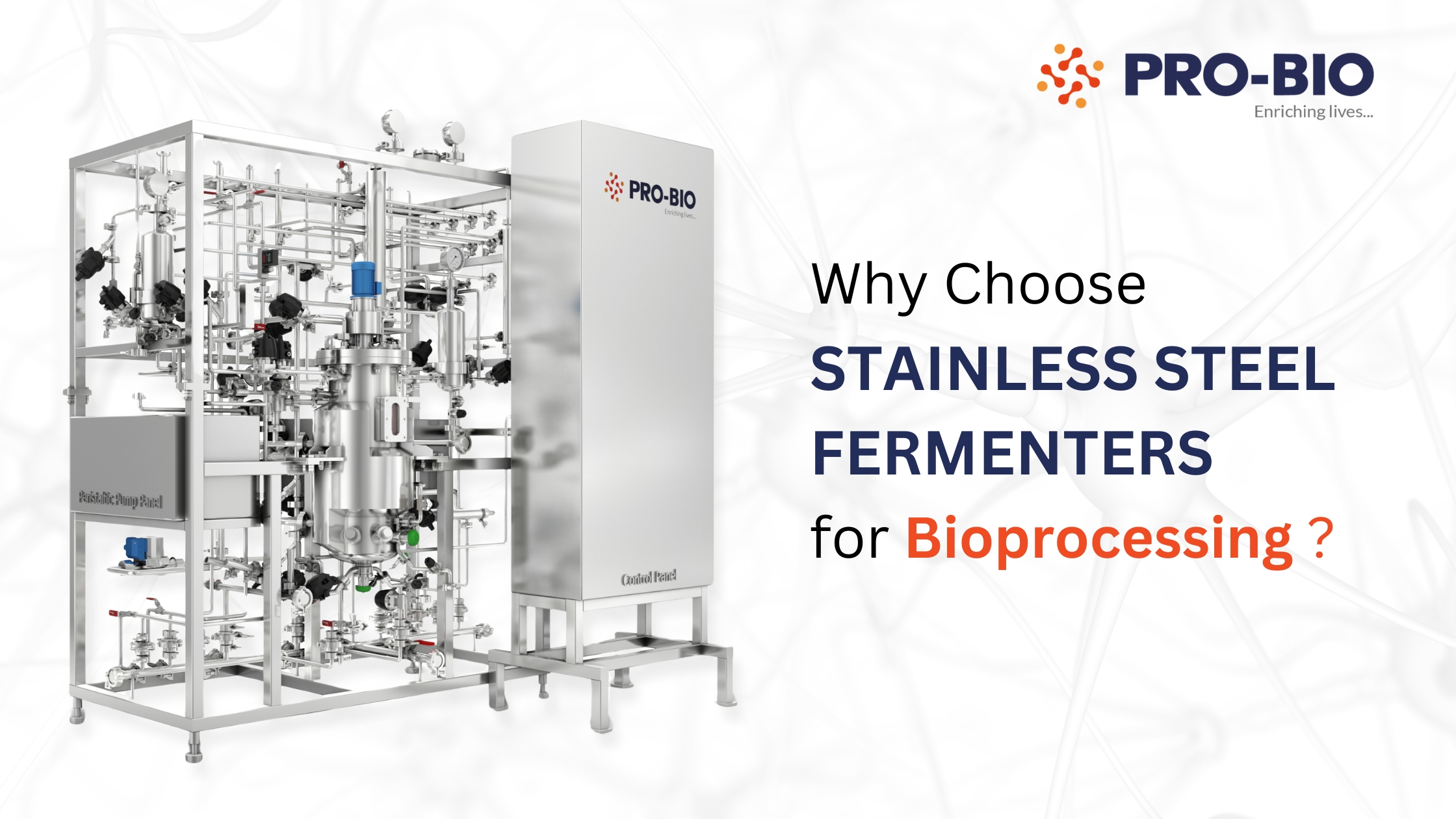

In the high-stakes world of biopharmaceutical production, where precision and sterility are non-negotiable, stainless steel fermenters have become an industry benchmark. These systems aren’t just vessels—they’re critical components designed to support advanced fermentation processes. From their material composition to their role in maintaining process integrity, let’s explore how stainless steel fermenter processing systems are transforming Advanced Biopharmaceutical Manufacturing with unparalleled efficiency and reliability.

A Barrier Against Corrosion: The Science of Chromium Oxide

The secret to stainless steel’s resilience lies in its unique alloy composition. Central to this is chromium, which reacts with atmospheric oxygen to create a self-renewing chromium oxide film. This molecular barrier effectively protects the industrial fermenter from corrosive agents such as acids, solvents, and alcohols generated during fermentation. Unlike other materials, stainless steel retains its structural integrity under harsh conditions, ensuring uninterrupted production cycles in biopharma manufacturing plants

Sterility First: Smooth Surfaces for Contamination Control

Maintaining sterility is paramount in biopharmaceutical fermentation, and stainless steel delivers unmatched performance in this regard. Its smooth, non-porous surface inhibits microbial attachment and biofilm formation, common risks in fermentation environments. Moreover, the material is compatible with Clean-In-Place (CIP) and Steam-In-Place (SIP) systems, enabling thorough sterilization without disassembly. This ensures compliance with stringent regulatory requirements for aseptic manufacturing, making it an ideal choice for fermentation process equipment used in biopharma plants and machineries.

Built to Endure: Strength and Durability

Stainless steel fermenter equipment is engineered to withstand the rigors of industrial bioprocessing. Their high tensile strength allows them to endure internal pressures and mechanical stresses during fermentation. Additionally, their resistance to wear and tear reduces downtime and maintenance costs, offering a robust solution for continuous or large-scale operations.

Precision in Temperature Control

Fermentation is a temperature-sensitive process, where even slight variations can impact product quality. Stainless steel’s excellent thermal conductivity supports precise temperature regulation, ensuring uniform heat distribution across the fermenter. Whether used for high-temperature microbial fermentation or cold enzyme reactions, stainless steel bio fermenters adapt seamlessly to a wide range of applications in biopharma processing.

Non-Reactive Material for Process Safety

In biopharma, where contamination can jeopardize entire batches, the non-reactive nature of stainless steel is a game-changer. The material resists chemical reactions with media, buffers, and active ingredients, safeguarding product purity. This is especially crucial for biologics and APIs, where even trace impurities can have significant consequences. As a trusted manufacturer of fermenters, we ensure our systems maintain the highest standards of safety and reliability.

A Polished Finish: More Than Aesthetics

While often overlooked, the polished finish of stainless steel fermenters contributes significantly to their performance. A smooth, mirror-like surface reduces particulate build-up and enhances cleanability. Additionally, the finish extends the equipment’s lifespan by minimizing the risk of localized corrosion—a critical feature in long-term biopharma processing

Sustainability in Manufacturing

With growing emphasis on environmentally conscious production, stainless steel’s recyclability makes it a preferred choice. Its ability to be reused without losing quality supports sustainable practices while reducing waste, aligning perfectly with the biopharma industry's move toward greener solutions. This makes it a staple for biopharma industry focused on eco-friendly manufacturing.

Design Flexibility for Tailored Solutions

One of the standout features of stainless steel is its adaptability. From modular fermenters to jacketed systems for precise temperature control, stainless steel allows for a high degree of customization. This flexibility ensures that each industrial fermenter meets the unique requirements of diverse bioprocessing applications, from cell culture to vaccine production.

Conclusion

Stainless steel fermenters are indispensable in biopharmaceutical manufacturing, offering a perfect combination of performance, reliability, and sustainability. Their corrosion resistance, sterility, durability, and adaptability enable efficient and compliant bioprocessing, making them a cornerstone of modern biopharma facilities. At Pro-Bio, we specialize in delivering advanced fermenter processing systems tailored to the unique needs of your biopharma manufacturing plant. As a leading biopharma equipment manufacturer and biotechnology equipment manufacturer, we’re here to elevate your processes and achieve consistent, high-quality results. Partner with us to optimize your fermentation process equipment and unlock the full potential of Advanced Biopharmaceutical Manufacturing.