Choosing the right bioreactor for cell culture in a biopharmaceutical manufacturing plant isn’t just about capacity or footprint, it’s about performance, compliance, and process scalability.

With so many configurations available, from lab-scale bioreactors to pilot-scale and GMP production systems, selecting the right platform is essential for biologics developers..

This blog outlines the most important factors to consider when selecting a stainless steel bioreactor for cell culture, especially for companies manufacturing monoclonal antibodies, vaccines, or recombinant proteins.

Why Bioreactor Selection Matters

A bioreactor is the engine of upstream processing. If it fails due to poor oxygen transfer, inconsistent pH, or excess shear you risk a full batch loss.

The right system helps you:

• Maximize cell viability and product yield• Ensure process repeatability from lab to plant

• Simplify validation and audit readiness

• Seamlessly scale into downstream purification

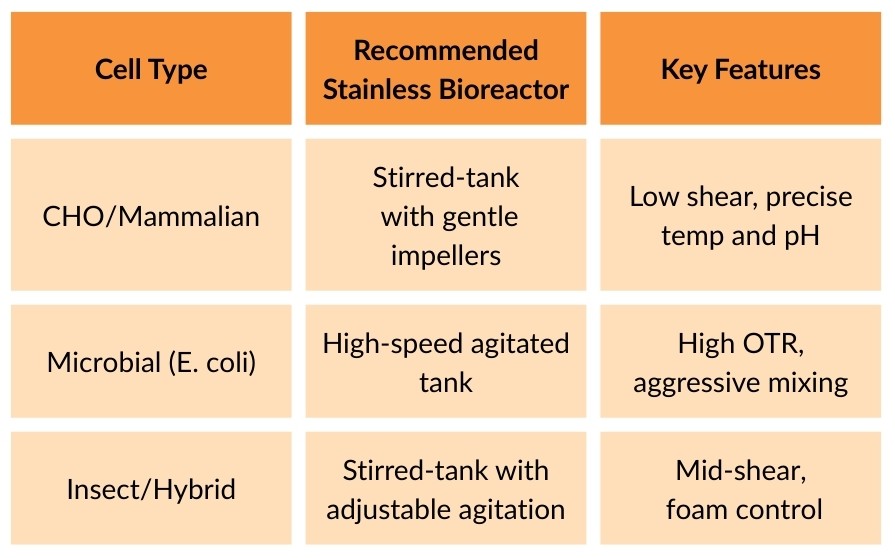

1. Match the Bioreactor to Your Cell Line

Different cells have different needs:

Know your cell line’s oxygen demand, shear sensitivity, and pH tolerance. These define your bioreactor design.

2. Choose the Right Scale: Lab, Pilot, or Production

Bioreactor scale impacts process control and consistency:

• Lab-scale (0.5–10L): R&D and media optimization• Pilot-scale (10–200L): Tech transfer and validation

• Production-scale (500–2,000L+): Full GMP manufacturing

At Pro-Bio, we ensure design consistency across all scales including matching kLa, impeller specs, and sensor configurations to make scale-up frictionless.

3. Why We Recommend Stainless Steel Bioreactors

We specialize in stainless steel bioreactors because they:

• Are robust and ideal for long-term, large-volume use• Support CIP/SIP for automated cleaning and sterilization

• Are fully customizable to your process

• Offer lower cost-per-batch over time compared to single-use

While single-use systems are popular for clinical or niche products, stainless steel is the preferred platform for commercial bio manufacturing, consistency, and regulatory compliance.

4. Control System & Automation

Automation ensures consistency, compliance, and traceability. Look for:

• PLC/SCADA control systems with HMI panels• Recipe-based process control

• 21 CFR Part 11-ready software with audit trails

• Alarm systems, batch logging, and remote monitoring

Pro-Bio’s stainless steel bioreactors include validated automation platforms, designed to support cGMP manufacturing and integration with MES/LIMS.

5. Optimize Agitation and Aeration

Mixing and aeration directly impact cell growth and viability. Key considerations:

• Top or bottom-mounted agitators• Multiple impeller configurations (Rushton, marine, pitched)

• Fine-bubble spargers for optimized gas transfer

• Backpressure and gas blend control for DO precision

Our systems are engineered to deliver consistent kLa and allow fine-tuned oxygen and shear control even at production scale.

6. Compliance, Documentation & Validation

GMP compliance is non-negotiable. Your bioreactor supplier must provide:

• ASME BPE-certified surface finishes• Weld logs, material traceability, and electro polish reports

• FAT/SAT protocols with full IQ/OQ packages

• Automation validation and software compliance

At Pro-Bio, we deliver complete documentation for regulatory readiness, backed by on-site commissioning and training support.

FAQs

Stainless steel stirred-tank bioreactors with low-shear impellers and automated controls are ideal for CHO cells.

Stainless steel is better for commercial-scale, repetitive manufacturing due to its durability and CIP/SIP readiness.

FAT/SAT, IQ/OQ protocols, weld logs, electro polish certificates, and 21 CFR Part 11 software compliance.

Final Thoughts

Choosing a stainless steel bioreactor for your biopharma facility means committing to long-term performance, regulatory success, and scalability.

At Pro-Bio, we specialize in engineering lab to production-scale bioreactors designed for biologics:

• Built to GMP and ASME BPE standards• Fully automated with validated software

• Backed by global service, documentation, and process expertise

Ready to Choose the Right Bioreactor?

📞 Talk to Our Experts📩 Request a Quote

🔎 Explore Our Bioreactor Systems